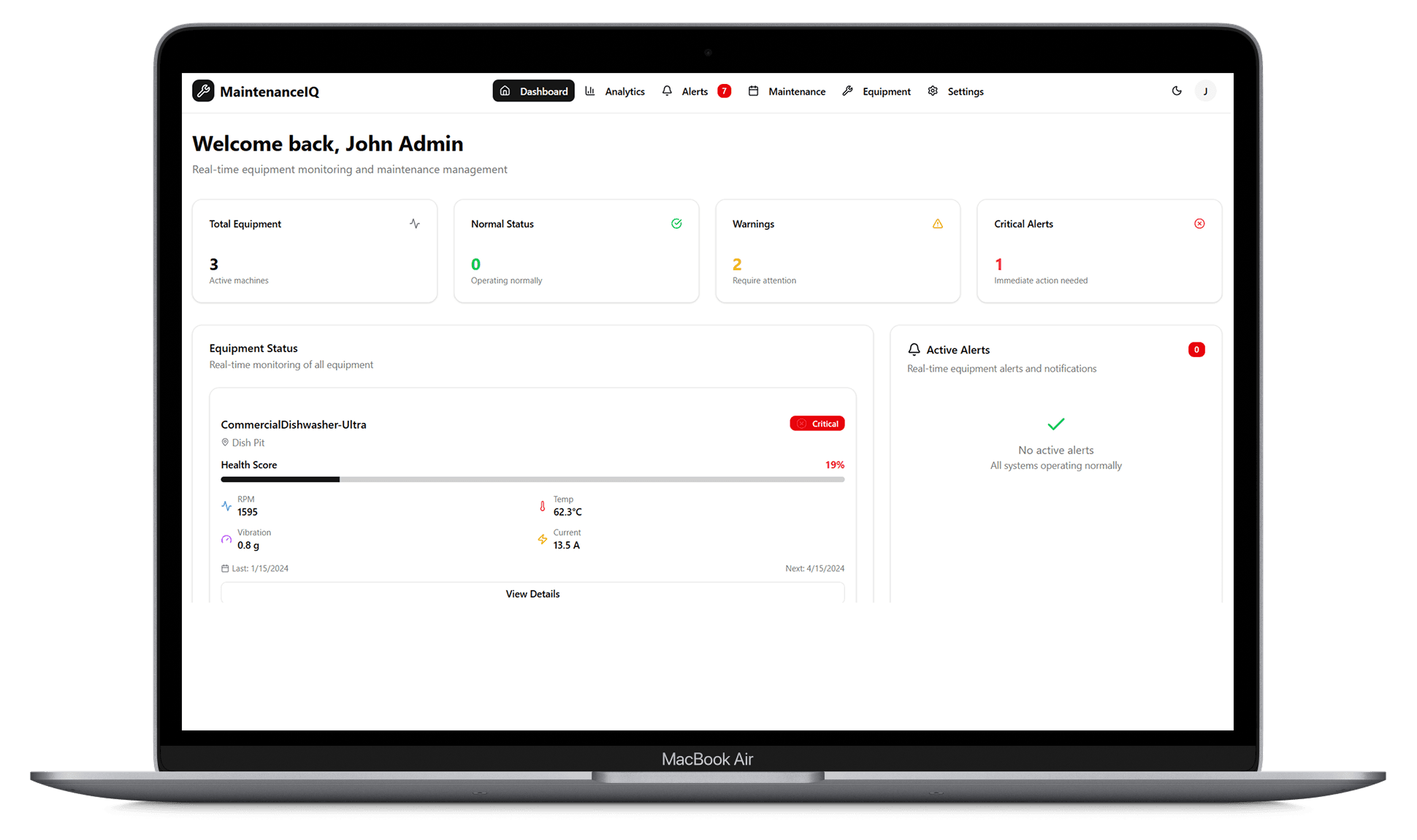

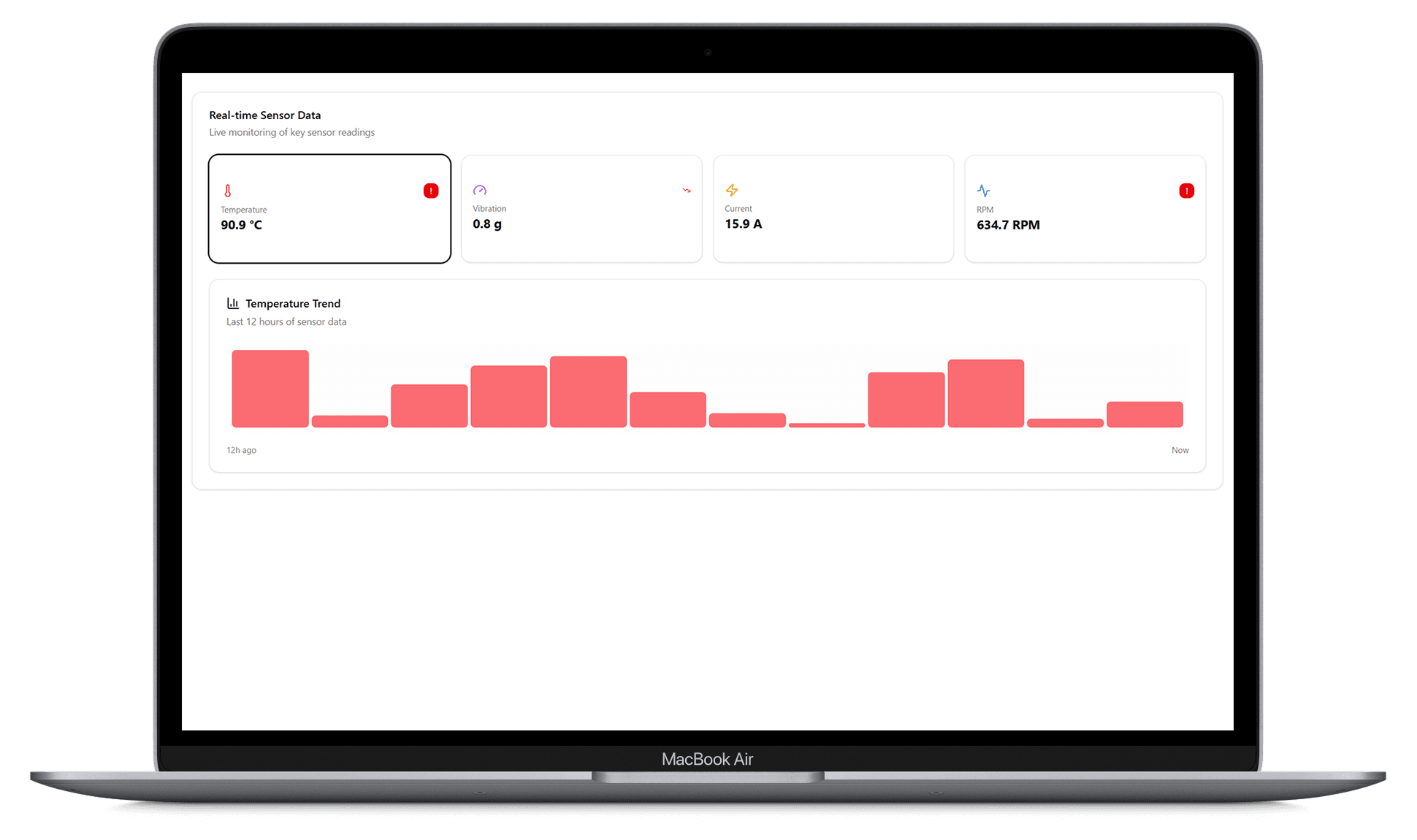

This system continuously monitors the health of critical machinery by analyzing real-time sensor data. It predicts potential failures before they occur, transforming maintenance strategy from reactive to proactive and ensuring maximum asset reliability and operational uptime.

The predictive maintenance engine utilizes advanced analytics and machine learning algorithms to identify patterns and anomalies in the sensor data. This allows it to forecast equipment degradation and potential failures before they occur, enabling maintenance teams to take proactive measures. By optimizing maintenance schedules and reducing unplanned downtime, the system enhances operational efficiency, extends equipment lifespan, and minimizes costly repairs or replacements. This innovative approach transforms maintenance from a reactive to a predictive process, maximizing the productivity and reliability of critical assets.